CIVIL&ENVIRONMENTAL

ENGINEERING

WEBZINE2018 Vol.1, No.1All about SWEET Lab.

Today, we want to interview the SWEET laboratory in the Department of Civil and Environmental Engineering, KAIST-

What are the main research topics of SWEET Lab.?

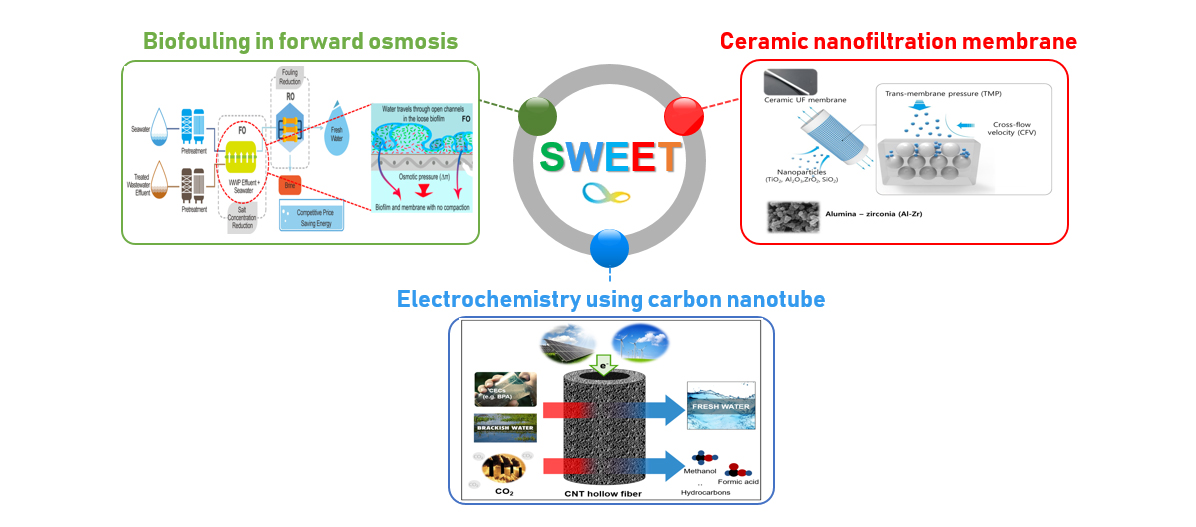

- Sustainable Water Environment and Energy Technology (SWEET) laboratory is studying to solve global water and energy problems under guidance of Prof. Seoktae Kang. Our research topics can be specifically divided into three groups including

-

- 1) Mechanistic investigation of biofouling in osmotically-driven (forward osmosis) membrane processes,

- 2) Novel preparation and application of ceramic nanofiltration membrane processes, and

- 3) CNT membrane-based electrochemical system for water treatment and energy production

Main research areas of SWEET Lab.

-

What is forward osmosis membrane process?

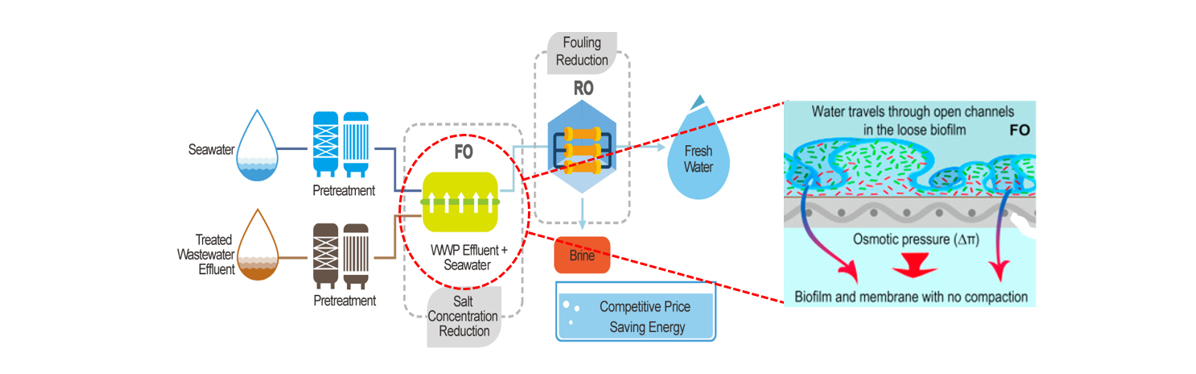

- Forward osmosis (FO) membrane process is an osmotically-driven process that uses a semi-permeable membrane to separate water from dissolved solutes. In contrast to the reverse osmosis process which uses the hydraulic pressure as the driving force, the driving force for FO is an osmotic pressure gradient, generated by the difference in the salt concentration between feed and draw solution. Due to the advantage in low fouling and low pressure during the operation, the application of FO has been gradually increased in the wastewater reuse, dewatering, and hybrid desalination processes. However, like other membrane-based water treatment processes, fouling phenomenon is an obstacle to overcome.

Schematic diagram of FO process applied in wastewater reuse and biofouling phenomenon in FO

-

What kind of researches does SWEET Lab. do regarding biofouling?

- Membrane fouling can be defined as the decrease of membrane performance due to the attachment and deposition of solutes or particles in the membrane pores or on the membrane surface. Among membrane foulings, biofouling, the deposition and growth of microbial biofilm, is regarded as the most undesirable circumstance due to the secretion of organic foulants as well as the growth of microorganism. Our group has focused on revealing the mechanism of biofouling in FO process to mitigate biofouling through various methods in both laboratory and pilot scale operations. In particular, investigations of quorum sensing inhibitors and bacterial growth inhibitors were successively carried out. Moreover, pilot scale FO process was installed and is operated now to establish the operational protocol to control the biofouling in FO process

-

What is ceramic membrane?

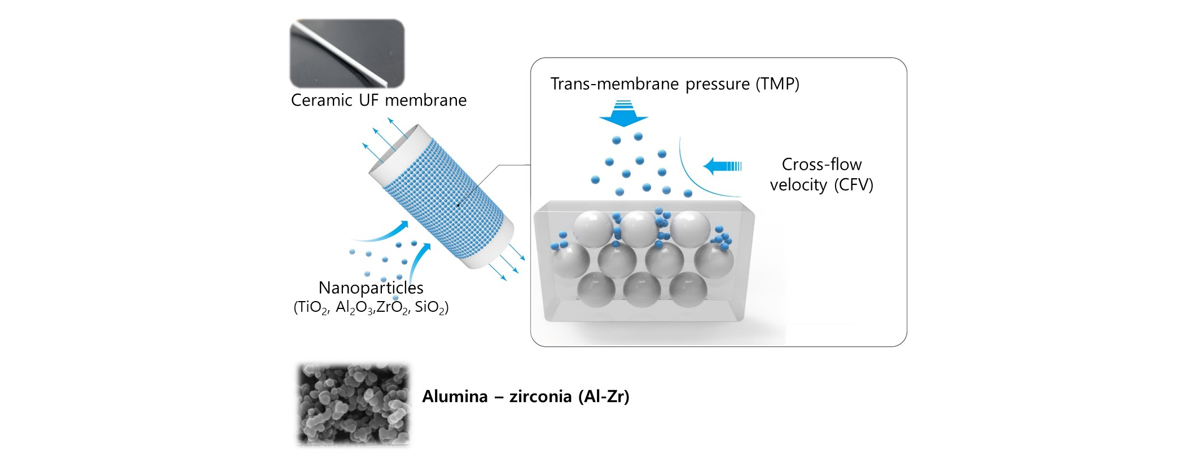

- What comes to your mind when you hear about ceramic? Maybe, you could imagine a pottery made at a high temperature. Similarly, ceramic membrane is also fabricated using clay, silt, and sand at over 700 degrees. Ceramic membranes are of great interest in separation technology because of their higher chemical, thermal and mechanical stability compared to organic membranes. Recently, ceramic membranes have been applied mostly as forms of microfiltration (MF) and ultrafiltration (UF) membrane to remove contaminants such as colloid, suspended solids, and virus in water treatment process.

-

Is there any limitation for the wider application of ceramic membrane?

- Although ceramic membranes exhibit superior properties of thermal, mechanical, and chemical resistivity compared to those of polymeric membranes, their use in advanced water treatment processes has been limited due to difficulties in controlling the pore size under sub-nanometer scale, which possesses the weight cut-off (MWCO) of ~ 1,000 Dalton or smaller. To solve this problem, our group patented a simple and novel surface coating method, called filtration-coating, to prepare the ceramic NF membranes. This method is expected to control the MWCO by preparing the various size of nanoparticles compatible with desired pore size, thus widen the area of application even at extremely harsh conditions such as radioactive-contaminated and industrial wastewater with high temperature. Moreover, our group applied the ceramic NF membranes in combination with advanced oxidation processes to remove micropollutants, precursors of disinfection by-products, tastes & odor-causing organic matters, virus, and so on in a single reactor.

A schematic diagram of the novel filtration-coating method for the preparation of ceramic NF membrane

-

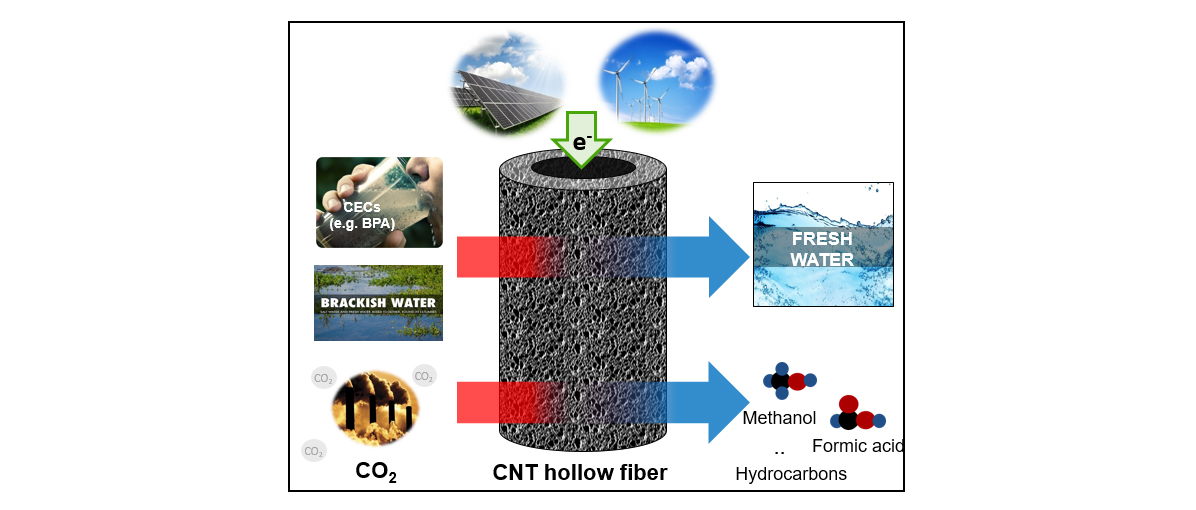

What makes the commercialization of electrochemical system difficult?

- In an electrochemical system composed of conventional plate-type electrode, the conversion of reactant is low due to the limitation of mass transfer rate on the surface of electrode. The limited reaction rate hindered the commercialization of electrochemical systems in the environmental application compared to biological and/or chemical reactors.

-

What is the CNT hollow fiber membrane?

- Our group fabricated an electrode in the form of a hollow-fiber type membrane fully composed with carbon nanotubes (CNT), named CNT hollow-fiber membrane or CHF. CNT provides a good electrical conductivity and the hollow-fiber filter structure allows the electrolytes to flow through the CHF electrode, thus overcomes the limitation in mass transfer.

-

What kind of researches does SWEET Lab. do regarding above research topic?

- CHF could be applied in almost all areas of electrochemical processes including oxidation, reduction, capacitive interaction, adsorption, oil separation, CO2 conversion, catalytic templates, etc. Currently, following applications are considered.

-

- i) Electrochemical oxidation of contaminants of emerging concerns (CECs), which were hardly removed in conventional treatment process

- ii) Electrochemical reclamation of valuable resources (e.g., copper) or separation of salts in brackish water

- iii) Electrochemical reduction of carbon dioxide through biological and chemical catalysts

Application of CNT hollow fiber in the water treatment and carbon dioxide conversion

-

What are the future goals for SWEET Lab.?

- The goal of SWEET Lab. is to solve emerging issues by leading-edge technologies not only in a laboratory scale, but also in a real field.